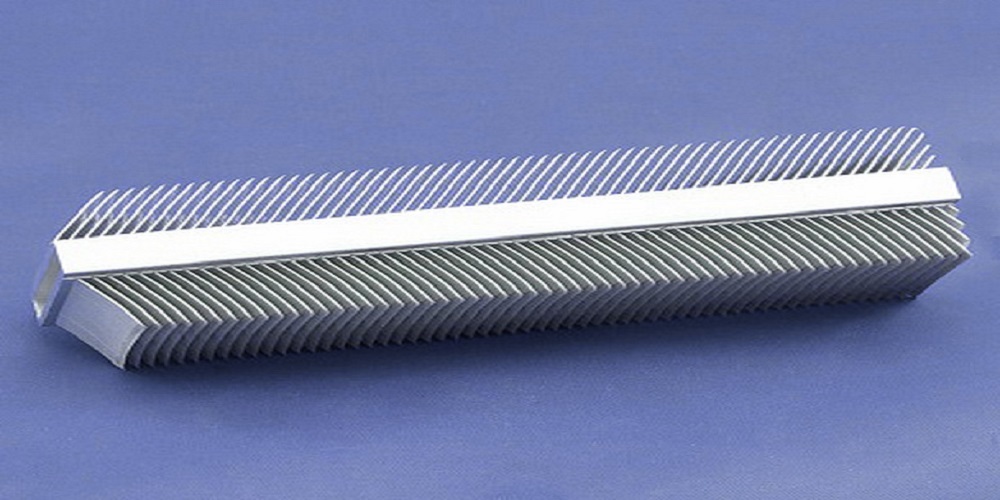

Custom heatsinks are an essential component in high-performance electronics. Particularly in industries where equipment must operate in harsh environments, they prevent overheating and ensure peak performance. Unlike generic heatsinks, which might not provide the same level of efficiency, custom heatsinks are made to meet specific needs. With examples from various industries, this article will examine why custom heatsinks are essential for high-performance electronics.

Preventing Overheating

Electronics face a lot of challenges from heat. Components that produce heat are easily prone to overheating, malfunctioning, and catastrophic system failure. Custom heatsinks are essential in resolving this issue by diverting heat away from delicate parts like microprocessors and memory chips. This keeps the device from overheating and makes sure it runs at a safe temperature.

Custom heatsinks are used in the automotive industry to cool vital parts like engine control units (ECUs), power inverters, and battery management systems. Extreme operating conditions, such as high temperatures and vibrations, can lead to these components overheating. Custom heatsinks made specifically for these parts offer a dependable cooling solution that guarantees peak performance.

Optimizing Performance

Custom heatsinks help to improve the performance of electronic devices by preventing overheating as well. Components in high-performance electronics produce a lot of heat, which can greatly impact how well they work. Custom heatsinks created with a focus on a particular component offer effective cooling solutions that guarantee peak performance.

Custom heatsinks, for instance, are used in the computer industry to cool expensive processors and graphics cards. Due to the high heat produced by these components, they may throttle and perform worse. Custom heatsinks made for these parts offer effective cooling that guarantees peak performance.

Extends Lifespan of Devices

In addition to optimizing performance, custom heatsinks also extend the lifespan of electronic devices. High operating temperatures hasten the deterioration of components, which reduces their lifespan. The device’s lifespan is increased, and the degradation rate is decreased by using custom heatsinks to keep parts operating within a safe temperature range.

Design Flexibility

Custom heatsinks provide a level of design flexibility unmatched by generic heatsinks. Custom heatsinks can be made in a variety of shapes, sizes, and materials to suit the needs of particular devices because they are made to meet specific requirements. This design adaptability degree ensures that the heatsinks offer the components’ most effective cooling solution.

For instance, special heatsinks are created in the aerospace sector to match the sizes and shapes of particular spacecraft and satellite components. Extreme operating conditions, such as high radiation and vacuum, can impact these components’ performance. These components can be fitted with specific heatsinks to provide effective cooling solutions that guarantee maximum performance and dependability.

Cost-Effective

Even though custom heatsinks initially seem pricey, they ultimately provide a cost-effective solution. Custom heatsinks are created to meet particular specifications, making sure they offer the best cooling solution. With this level of efficiency, fewer additional cooling methods—like fans, which can be expensive to install and maintain—are required.

Custom heatsinks are used in the telecommunications sector to cool base station parts like radio frequency modules and power amplifiers. These components must have effective cooling methods to ensure peak performance because they produce a lot of heat. Custom heatsinks made specifically for these parts offer an affordable cooling solution that guarantees maximum performance and dependability.

Conclusion

High-performance electronics depend heavily on custom heatsinks to maintain peak performance and avoid overheating. In contrast to generic heatsinks, custom heatsinks offer design flexibility, are more affordable, and are made to meet specific needs. The significance of custom heatsinks cannot be overstated, given the rising demand for high-performance electronics. They offer effective cooling solutions that guarantee maximum performance and dependability, making them crucial in a variety of sectors, including computer technology, automotive, aerospace, and telecommunications.